The Power of Comprehensive Sheet Metal Fabrication Services

We Offer a Wide Range of Services with Extensive In-House Technologies to Meet Our Clients’ Sheet Metal Fabrication Needs.

Steel Fabrication India possesses the skilled workforce, exceptional quality standards, cutting-edge technology, and solid market reputation necessary to propel your business toward success. Our team of experienced professionals is dedicated to providing top-notch services that meet and exceed industry benchmarks.

The breadth of our expertise is evident in the variety of high-volume precision metalwork products we produce, each benefiting from our meticulous design engineering process. Consider the diverse range of products we expertly fabricate: robust tanks for industrial use, durable electrical enclosures that ensure safety and reliability, and sturdy brackets for earth-moving equipment that withstand the harshest conditions.

We also specialize in creating sleek kiosks and vending machines designed for modern convenience, as well as sophisticated point-of-sale units that enhance retail efficiency. Our capabilities extend to crafting complex processing and packaging systems essential for streamlined production lines, along with advanced HVAC equipment indispensable for maintaining optimal environmental control. These examples barely scratch the surface of what we can achieve together—let us help you realize your vision with unparalleled precision and innovation.

Steel Fabrication India is not merely a leader in the metal fabrication industry; it is an indispensable catalyst for success across a multitude of business sectors. This distinguished company boasts a formidable combination of highly skilled personnel, cutting-edge technology, and an unwavering commitment to quality. Their expertise extends far beyond mere metalworking—they are architects of excellence, meticulously crafting solutions that elevate projects to new heights.

With their stellar reputation and proven track record, Steel Fabrication India stands as your premier partner in achieving outstanding results for any project you undertake. Whether you’re navigating complex architectural endeavors or pioneering innovative industrial applications, their unparalleled capabilities ensure that your vision is transformed into reality with precision and finesse.

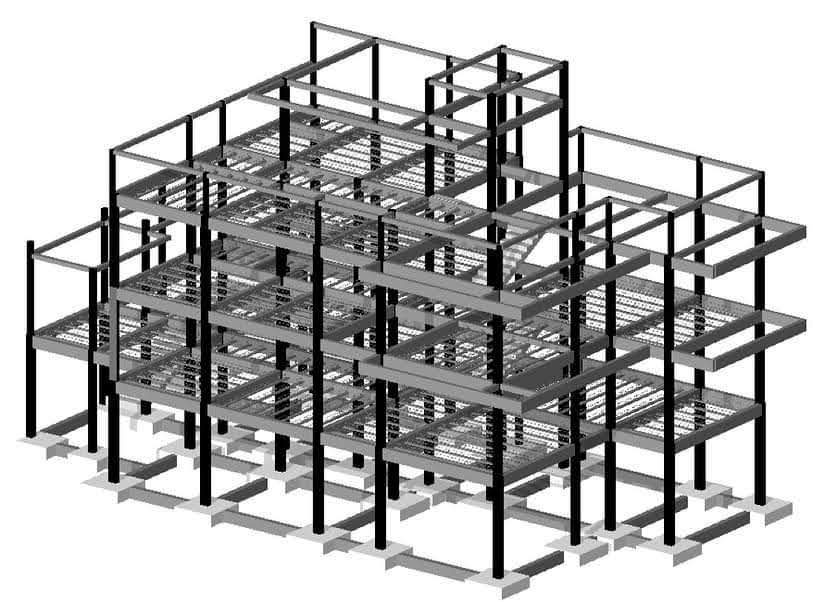

Holistic Design Engineering Process

Our design engineering process stands out in the industry due to its comprehensive approach, which ensures that every product not only meets but often exceeds expectations. This process is particularly beneficial for high-volume precision metalwork products. Here are some prime examples of items that reap significant advantages from our expertise:

– Tanks: Essential for industries such as chemicals, water treatment, and food processing, our tanks are designed for durability and compliance with the highest safety and quality standards.

– Electrical Enclosures: These protect critical electrical components from environmental factors and are engineered for functionality and ease of maintenance.

– Brackets for Earth Moving Equipment: Our brackets are crafted to offer supreme resilience and reliability, capable of withstanding the rigorous demands of construction and mining activities.

– Kiosks and Vending Machines: We produce aesthetically pleasing and secure kiosks and vending machines that stand the test of time, even in high-traffic environments.

– Processing and Packaging Systems: In the fast-moving consumer goods industry, our systems streamline operations, improving speed and accuracy in packaging and processing.

– HVAC Equipment: Essential for climate control in residential and commercial buildings, our HVAC components are synonymous with reliability and efficiency.

Technology and Innovation at the Core

At Steel Fabrication India, we leverage advanced technologies and innovative practices to deliver these complex and high-quality products. Our facilities are equipped with cutting-edge machinery and automation technologies that enhance precision and allow for high-volume production without compromising quality.

Quality That Leads to Market Success

Our commitment to quality is deep-rooted and evident in every project we undertake. Steel Fabrication India adheres strictly to international standards, ensuring that every product is robust, efficient, and capable of performing under the most demanding conditions. This dedication not only protects the integrity of your project but also enhances your reputation in the market, helping you to succeed and grow.

Partnership for Success

Choosing Steel Fabrication India means selecting a partner committed to your success. Our team works closely with each client, ensuring that every aspect of the project is handled with attention to detail and tailored to meet specific requirements. From the initial design to the final delivery, we are with you every step of the way, providing support and expertise that propels your project forward.

In conclusion, Steel Fabrication India represents the pinnacle of quality, expertise, and customer satisfaction in the metal fabrication industry. By entrusting us with your needs, you leverage a partnership that brings with it the people, technology, and reputation needed to excel in the marketplace. Let us help you turn your ambitious projects into successful realities.

Our team also specializes in creating exquisite Designer Panels, which are expertly used as Architectural Screens and Facades. These panels serve not only as functional elements but also elevate the aesthetic appeal of any architectural project. With our cutting-edge design and prototype capabilities, Fabricators India stands out for its ability to seamlessly transition from conceptualizing a single prototype to scaling up for full-scale production with remarkable efficiency. This means that we can quickly meet the demands of large-scale projects without compromising on quality or detail, offering you a streamlined process from inception to completion.

Our Design Capabilities:

- 1. Understand and ensure we can meet the customer’s requirement and desired specification

- 2. Carefully manage the initial design phase to ensure there are no delays

- 3. Agree timescales to meet our customer’s requirements

- 4. Provide prototypes or 3D models allowing early customer collaboration

- 5. Produce engineering drawings and bills of materials including supply chain